Bizim damgalama metal tabakası ürünlerimiz gelişmiş üretim süreçlerini ve yenilikçi tasarım kavramlarını entegre eden endüstriyel başyapıtlardır.Çeşitli endüstriler için ideal çözümler sunuyorlar..

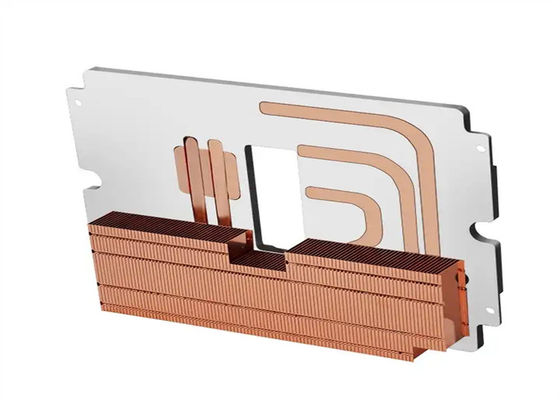

Malzeme seçimi açısından, soğuktan valye çelik levhaları, sıcaktan valye çelik levhaları, paslanmaz çelik levhaları ve alüminyum levhaları dahil olmak üzere yüksek kaliteli metal levhaları seçiyoruz.Kaynaktan ürün kalitesini sağlamakSoğuk valye edilmiş çelik levhalar mükemmel yüzey kalitesine ve yüksek boyut doğruluğuna sahiptir, bu da onları görünüm ve boyutlar için sıkı gereksinimlere sahip bileşenler üretimi için uygundur.Sıcak olarak yuvarlanan çelik levhalar yüksek dayanıklılığa ve iyi sertliğe sahiptirPaslanmaz çelik levhaları mükemmel korozyon direnci ve estetik çekiciliğe sahiptir.Estetik gerektirdiği sert ortamlarda ve senaryolarda uygulanabilir hale getirmekAlüminyum levhalar, hafif ve mükemmel ısı dağılım özellikleri nedeniyle elektronik ve otomotiv endüstrilerinde çok tercih edilir.

Üretim sürecinde, her damgalama işleminin doğruluğunu sağlamak için sayısal kontrol teknolojisi ile birleştirilen uluslararası lider damgalama ekipmanları ve hassas kalıplar kullanıyoruz.Çoklu hassas damgalama işlemleri ile, karmaşık şekillerin ve yüksek hassasiyetli boyutların işlenmesini sağlayabiliriz, boyut doğruluğu ± 0,1 mm'ye kadar, çeşitli sıkı tasarım gereksinimlerini karşılıyor.Gelişmiş metal tabakası işleme teknikleri, örneğin lazer kesimi, bükme ve kaynak, ürünlere daha yüksek dayanıklılık ve istikrar kazandırır.Lazer kesimi, pürüzsüz ve çürüksiz kesim kenarlarıyla karmaşık desenlerin yüksek hassasiyetli kesimini sağlayabilirBükme işlemi, bükme açısını ve boyutlarını hassas bir şekilde kontrol ederek ürünlerin montaj doğruluğunu sağlar.Kaynak teknolojisi, kaynaklı parçaların sağlam ve güvenilir olmasını sağlamak için argon yay kaynak ve nokta kaynak gibi çeşitli yöntemler kullanır, yanlış lehimlenme veya kayıp kaynak olmadan.

Performans açısından, damgalama metal levha ürünlerimiz mükemmel mekanik özelliklere ve çevreye uyumluluklara sahiptir.germe, ve darbe direnci, karmaşık çalışma koşullarında istikrarlı bir şekilde çalışmalarını ve ürünlerin kullanım ömrünü etkili bir şekilde uzatmalarını sağlar.Mükemmel korozyon direnci, nemli ve asidik veya alkali koşullar gibi sert ortamlarda bile iyi görünüm ve performanslarını korumalarını sağlarEk olarak, ürünler, püskürtme, galvanik kaplama, anodlama vb. gibi geniş bir yüzey işleme sürecine sahiptir.Sadece ürünlerin estetik çekiciliğini artırmakla kalmayıp koruma performanslarını da daha da iyileştirenpüskürtme işlemi, müşterinin ihtiyaçlarına göre çeşitli renk seçenekleri sağlayabilir, metal oksidasyonunu etkili bir şekilde önlemek için tekdüze ve yoğun bir kaplama oluşturabilir.Elektroplating, metal yüzeyinde yoğun bir metal koruyucu film oluşturabilirAnodizasyon işlemi, alüminyum levhaların yüzeyinde sert bir oksit filmi oluşturarak sertliklerini ve aşınma dayanıklılıklarını arttırır.

Bizim damgalama metal tabakası ürünleri yaygın olarak elektronik ve elektrikli cihazlar, mekanik ekipman, otomotiv üretim, iletişim ekipmanları,ve yeni enerjiElektronik ve elektrikli cihaz endüstrisinde, şasi, dolaplar ve kabuklar gibi bileşenler üretmek için kullanılırlar.Elektronik cihazlar için güvenilir fiziksel koruma ve ısı dağılımı desteği sağlamakMekanik ekipman endüstrisinde, farklı mekanik ekipmanların yapısal gereksinimlerini karşılamak için çeşitli mekanik bileşenler ve destekler işlenebilir.Otomotiv üretim endüstrisinde, araçların güvenliğini ve istikrarını sağlayan araç gövdeleri ve şasi gibi kilit parçaların üretiminde yer almaktadır.Ana istasyon dolapları üretmek için kullanılırlar.Yeni enerji endüstrisinde, yeni enerji sistemleri, yeni enerji sistemleri, yeni enerji sistemleri, yeni enerji sistemleri, yeni enerji sistemleri, yeni enerji sistemleri,Güneş fotovoltaik braketleri ve rüzgar enerjisi üretim ekipmanları gibi bileşenler için yüksek kaliteli metal tabakası ürünleri sağlıyoruz., yeni enerji endüstrisinin geliştirilmesine katkıda bulunur.

Her zaman müşteri ihtiyaçlarına yönlendirici ilke olarak bağlı kalırız ve kişiselleştirilmiş özelleştirme hizmetleri sunarız.Ürünlerin müşteri gereksinimlerini tam olarak karşıladığını sağlamak için her adımda müşterilerle yakın iletişim kuruyoruz.Aynı zamanda, hammadde denetimi, üretim sürecinin izlenmesi ve bitmiş ürün testlerine kadar her bağlantıyı titizlikle inceleyen tam bir kalite kontrol sistemi kurduk.% 100 ürün kalitesini sağlamakYüksek kaliteli ürünlerimiz, kapsamlı hizmetlerimiz ve iyi bir itibarımızla, birçok müşterinin güvenini ve desteğini kazandık.

Bizim damgalama metal tabakası ürünleri seçmek yüksek kalite, yüksek performans ve yüksek güvenilirlik seçmek anlamına gelir. Daha iyi bir gelecek yaratmak için sizinle birlikte çalışmak için sabırsızlanıyoruz!

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!